Michigan’s automotive industry is synonymous with high-volume, precision manufacturing. The backbone of this production lies in metal stamping, a process that demands not only cutting-edge stamping technology but also robust systems for managing the essential tooling and dies. For Michigan car manufacturers, optimizing every aspect of the stamping process, including the efficient storage and handling of tooling and stamping dies, is crucial for maintaining a competitive edge. This is where specialized tooling and stamping die racks become indispensable.

In this guide, we will delve into the critical role of Tooling And Stamping Die Racks For Michigan Car Manufacturers. We will explore how these racks are integral to streamlining operations, enhancing safety, and maximizing the lifespan of valuable stamping dies, ultimately contributing to the efficiency and precision that define Michigan’s automotive manufacturing prowess.

The Critical Role of Tooling and Stamping Die Racks in Automotive Manufacturing

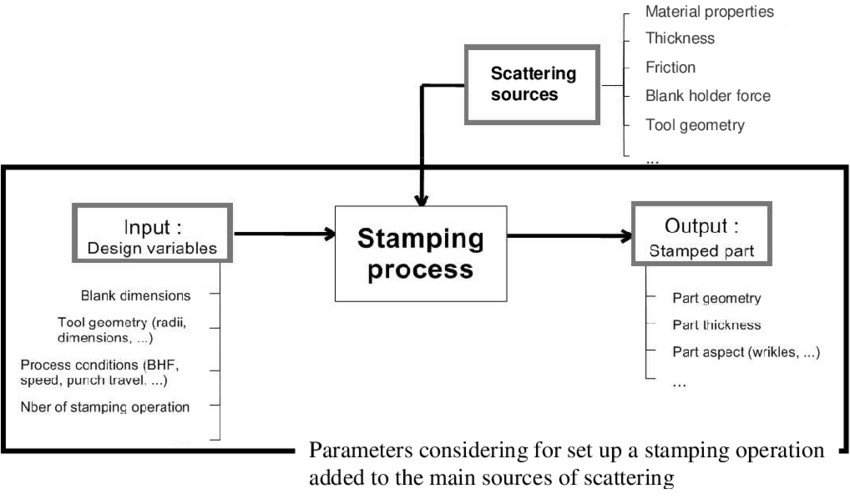

Michigan’s automotive sector relies heavily on metal stamping to produce a vast array of components, from body panels to intricate internal parts. The heart of any stamping operation is the tooling and dies – custom-engineered components that dictate the shape and precision of stamped parts. These dies are not only expensive but also delicate and require careful handling and storage to maintain their accuracy and longevity. Without efficient tooling and stamping die racks, automotive manufacturers in Michigan face significant challenges:

- Damage to Dies: Improper storage can lead to surface damage, misalignment, or even structural issues in stamping dies, resulting in costly repairs or replacements and production downtime.

- Inefficient Die Changes: Locating and retrieving the correct die quickly is essential for minimizing changeover times. Disorganized die storage leads to delays, impacting production schedules.

- Safety Hazards: Moving heavy dies manually or with inadequate equipment poses serious safety risks to personnel. Secure die racks are vital for safe storage and handling.

- Wasted Space: Unsystematic die storage can consume valuable floor space in manufacturing facilities, hindering workflow and productivity.

Investing in specialized tooling and stamping die racks addresses these pain points directly, offering a streamlined, safe, and efficient solution for managing these critical assets. For Michigan car manufacturers striving for operational excellence, these racks are not merely storage solutions; they are foundational elements of a high-performance stamping operation.

Supporting Progressive Die Stamping with Robust Racks

Progressive die stamping, a cornerstone of high-volume automotive parts production in Michigan, utilizes complex dies with multiple stations to progressively form a part with each press stroke. These progressive dies, while highly efficient, can be large and intricate, requiring specialized tooling and stamping die racks designed for their specific dimensions and weight.

Racks designed for progressive dies often feature:

- Heavy-duty construction: To support the substantial weight of progressive dies.

- Customizable shelving: To accommodate varying die sizes and configurations.

- Easy access mechanisms: Such as pull-out shelves or drawers, to facilitate die retrieval and installation in presses, minimizing changeover time crucial for Michigan’s fast-paced automotive production lines.

By implementing appropriate tooling and stamping die racks for progressive dies, Michigan car manufacturers can ensure these valuable tools are readily available, safely stored, and easily maintained, maximizing the efficiency of their high-volume stamping operations.

Die Racks for Deep Draw Stamping Operations

Deep draw stamping, essential for creating components with significant depth like automotive panels and housings, employs dies that, while potentially less horizontally expansive than progressive dies, still require robust and accessible storage. Tooling and stamping die racks for deep draw dies must consider the vertical profile of these tools and ensure stability during storage and retrieval.

Features of die racks optimized for deep draw stamping may include:

- Vertical orientation storage: To efficiently utilize vertical space and accommodate the shape of deep draw dies.

- Reinforced frames: To handle the concentrated weight distribution of these dies.

- Cranes or hoist integration: Designed for seamless integration with overhead lifting systems commonly used to move deep draw dies, enhancing safety and speed.

Michigan automotive manufacturers utilizing deep draw stamping benefit significantly from tooling and stamping die racks that are specifically engineered for these types of dies. This ensures the safe and efficient handling of dies critical for producing complex automotive shapes.

Accommodating Transfer Dies: Rack Solutions

Transfer die stamping, often used for larger or more intricate automotive components, involves moving parts between separate die stations via mechanical transfer systems. Transfer dies, similar to progressive dies in complexity, often consist of multiple die sets that need to be stored together for efficient setup and maintenance. Tooling and stamping die racks for transfer dies need to be adaptable and organized to manage these multi-part tooling systems.

Effective rack solutions for transfer dies might offer:

- Modular design: Allowing for flexible configuration to store complete transfer die sets together.

- Clearly labeled locations: For each die component within a set, ensuring quick and accurate retrieval during die changes.

- Proximity to press lines: Strategically positioned racks near transfer presses to minimize transport distances and changeover times.

For Michigan car manufacturers utilizing transfer die stamping for large automotive parts, well-organized tooling and stamping die racks are crucial for managing the complexity of these multi-stage die systems and maintaining efficient production flow.

Racks for Short-Run Tooling and Dies

While Michigan is known for high-volume automotive production, short-run stamping also plays a vital role, particularly in prototyping, aftermarket parts, and specialized vehicle manufacturing. Short-run stamping often utilizes simpler, more adaptable tooling. Tooling and stamping die racks for short-run operations need to be versatile and easily reconfigurable to accommodate a variety of die types and sizes.

Ideal features for short-run die racks include:

- Adjustable shelving: Providing maximum flexibility for storing diverse die dimensions.

- Mobile rack options: For easy relocation within the facility to support flexible production layouts.

- Lower capacity, cost-effective designs: Tailored to the potentially smaller scale of short-run tooling inventories.

Michigan automotive facilities engaged in prototyping or lower volume production can leverage adaptable tooling and stamping die racks to efficiently manage their tooling for short-run stamping, ensuring quick setup and changeover capabilities.

Material Considerations for Die Racks in Michigan’s Auto Climate

The durability and longevity of tooling and stamping die racks are paramount, especially in the demanding environment of Michigan’s automotive manufacturing plants. Material selection for these racks directly impacts their ability to withstand heavy loads, resist corrosion, and maintain structural integrity over years of use.

Common materials for robust tooling and stamping die racks include:

- Steel: Especially heavy-gauge steel, offers exceptional strength and load-bearing capacity, essential for supporting heavy stamping dies. Steel racks can be further enhanced with powder coating or other protective finishes to resist rust and wear in industrial environments.

- High-Strength Alloys: For specialized applications or extremely heavy dies, certain high-strength steel alloys may be used to provide maximum durability and safety.

Choosing the right materials for tooling and stamping die racks is a critical investment for Michigan car manufacturers, ensuring long-term reliability and safety in die storage and handling.

Precision and Quality in Die Rack Design and Manufacturing

Just as precision is critical in metal stamping itself, the design and manufacture of tooling and stamping die racks must also adhere to high standards of accuracy and quality. Dimensional accuracy and robust construction are essential to ensure dies are securely supported and easily accessible.

Key aspects of precision in die rack manufacturing include:

- Accurate Dimensions: Racks must be manufactured to precise dimensions to ensure proper die fit and stability. CNC machining and laser cutting techniques are often employed to achieve these tight tolerances.

- Welding Quality: For steel racks, high-quality welding is crucial for structural integrity and load-bearing capacity. Certified welders and rigorous inspection processes are essential.

- Load Testing: Reputable die rack manufacturers often conduct load testing to verify the rack’s capacity and safety under maximum load conditions.

- Quality Finishes: Durable powder coating or other protective finishes not only enhance aesthetics but also provide corrosion resistance and extend the lifespan of the racks.

Michigan car manufacturers should prioritize tooling and stamping die racks from manufacturers who demonstrate a commitment to precision and quality in their design and fabrication processes. This ensures long-term reliability and safety in die management.

Optimizing Lead Times and Production Efficiency with Effective Die Racks

In the fast-paced automotive industry, minimizing lead times and maximizing production efficiency are constant imperatives. Efficient tooling and stamping die racks play a crucial role in achieving these goals by streamlining die changes, reducing downtime, and optimizing workflow.

How effective die racks contribute to efficiency:

- Reduced Die Changeover Time: Well-organized and accessible racks minimize the time spent locating and retrieving dies, significantly speeding up die changes and reducing press downtime.

- Improved Inventory Management: Clearly labeled and systematically organized racks improve die inventory management, preventing lost or misplaced dies and ensuring efficient utilization of tooling assets.

- Enhanced Workplace Safety: Safe and stable die racks reduce the risk of accidents associated with manual die handling, contributing to a safer and more productive work environment.

- Optimized Floor Space: Vertical or high-density die rack systems maximize storage capacity within a given footprint, freeing up valuable floor space for production activities.

By investing in well-designed tooling and stamping die racks, Michigan car manufacturers can realize significant gains in production efficiency, reduce operational costs, and enhance their competitive advantage.

Frigate’s Expertise in Tooling and Die Rack Solutions for Michigan Car Manufacturers

At Frigate, we understand the critical importance of efficient tooling and die management for Michigan’s automotive manufacturers. While our core expertise lies in providing high-precision metal stamping components, we recognize that the infrastructure supporting these operations, including tooling and stamping die racks, is equally vital. We partner with leading manufacturers of die rack systems to offer our clients in the Michigan automotive sector comprehensive solutions for their stamping needs.

We can assist Michigan car manufacturers in:

- Sourcing high-quality, customized tooling and stamping die racks tailored to their specific die types, press configurations, and facility layouts.

- Consulting on die rack system design and implementation to optimize workflow, safety, and space utilization.

- Integrating die rack solutions as part of a broader, efficient metal stamping ecosystem.

While Frigate does not directly manufacture die racks, our deep understanding of the metal stamping process and our commitment to providing complete solutions for our automotive clients in Michigan positions us as a valuable partner in optimizing your tooling and die management infrastructure.

Conclusion

For Michigan car manufacturers, achieving and maintaining a competitive edge in the automotive industry hinges on optimizing every facet of their production processes, starting with the very foundation of metal stamping: the tooling and dies. Tooling and stamping die racks are not simply storage devices; they are integral components of an efficient, safe, and high-performance stamping operation. By investing in robust, well-designed die rack systems, Michigan automotive companies can protect their valuable tooling assets, streamline die changes, enhance workplace safety, and ultimately drive greater productivity and profitability.

If you are a Michigan car manufacturer seeking to optimize your metal stamping operations, consider partnering with Frigate. We can connect you with industry-leading solutions for tooling and stamping die racks and provide expert guidance to enhance your entire stamping ecosystem. Contact Frigate today to explore how we can help you elevate your manufacturing capabilities and stay ahead in the competitive automotive market.