Every auto repair shop buzzes with the activity of various power tools, but are you truly familiar with them all? The landscape of automotive repair is shifting, with cordless Power Tools For Working On Cars rapidly gaining prominence over their corded counterparts. In modern garages, you’re increasingly likely to find a greater arsenal of cordless tools. This article dives into the essential cordless power tools that should be in any well-equipped garage for efficient and effective car repairs. Let’s explore the must-have cordless tools that will revolutionize your car maintenance and repair tasks.

The Rise of Cordless Power Tools for Mechanics

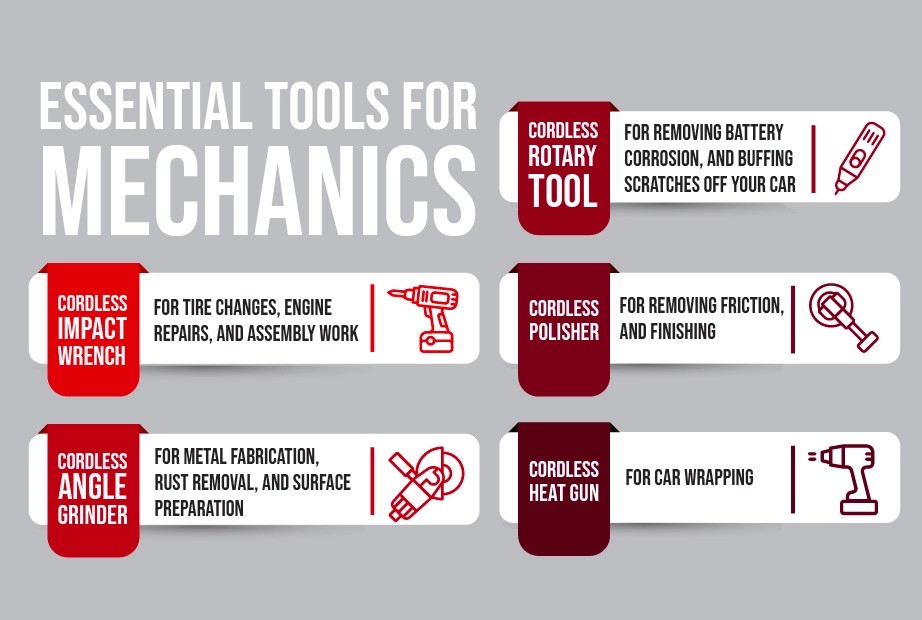

Mechanics’ cordless tools are indispensable across a broad spectrum of applications, from diagnosing intricate automotive issues to executing precise repairs and performing routine maintenance on cars, motorcycles, industrial equipment, and even aircraft. While the specific selection of essential cordless power tools for mechanics depends on the mechanic’s specialization and the tasks at hand, certain tools are universally valuable. Here’s a breakdown of the most commonly essential cordless power tools that every mechanic should consider.

Cordless Impact Wrench: The High-Torque Hero

It’s almost impossible to imagine a functional repair shop without an impact wrench. When faced with high-torque applications, a robust impact wrench paired with a comprehensive socket set becomes indispensable. Their primary function is efficiently loosening and tightening stubborn fasteners, particularly lug nuts on cars and trucks. It’s crucial not to confuse impact wrenches with impact drivers. Here’s how to differentiate them:

- A standard impact wrench is designed to accommodate ½-inch drive sockets in various sizes, perfectly suited for wheel lugs.

- An impact driver utilizes a ¼-inch hex shank for bits, designed for driving screws and smaller fasteners.

Before cordless technology took hold, pneumatic impact wrenches, powered by compressed air, were the industry standard in professional garages. However, advancements in battery technology have propelled cordless impact wrenches to the forefront. These tools now offer comparable power, improved portability, and competitive pricing, making them a compelling alternative to pneumatic models. The standout advantage of these cordless mechanics’ power tools is unmatched portability. Mechanics can move freely around vehicles, quickly loosen lug nuts, and work without the constraints and hazards of air hoses or power cords cluttering the workspace. This freedom enhances efficiency and safety, making cordless impact wrenches a cornerstone of any modern mechanic’s toolkit.

Cordless Angle Grinder: Versatility in Cutting and Grinding

The angle grinder is a multifaceted tool with several key components:

- A high-speed spinning wheel designed for cutting, grinding, and polishing various materials.

- A safety guard to protect the user from debris and sparks.

- A durable housing to encase the motor and gears.

While not always visible in every corner of a garage, the angle grinder is essential for numerous car repair tasks. Rust and old paint removal are among its most frequent applications.

By utilizing different types and sizes of abrasive wheels, mechanics can achieve precise results for various grinding and surface preparation tasks. Furthermore, the angle grinder’s metal-cutting capability makes it invaluable for tasks like sectioning damaged car body panels or exhaust components. The cordless angle grinder elevates control and maneuverability, especially in tight spaces or when working on vehicle undercarriages. This enhanced control leads to more accurate and safer operations, underlining the cordless angle grinder’s importance as a power tool for working on cars.

Cordless Rotary Tool: Precision Detailing and Repair

Among the array of cordless mechanic tools, rotary tools might initially seem less robust for heavy-duty vehicle work. However, they are exceptionally versatile and efficient for a multitude of detailed tasks.

- Removing battery terminal corrosion, offering a more effective solution than brushes.

- Polishing out minor scratches and blemishes on car, truck, RV, or motorcycle paintwork.

- Cleaning and smoothing scratches using rubbing compounds and felt polishing wheels in circular motions.

For paint correction, after applying and drying the rubbing compound, it’s removed with a soft microfiber cloth, followed by the application of a polishing compound. These steps, performed in circular motions with a rotary tool, can significantly revitalize a vehicle’s appearance. The cordless nature of these tools grants superior control and maneuverability, enabling work in various positions without the hindrance of cords. This precision and portability make cordless rotary tools ideal for intricate detailing and small repairs, solidifying their place as essential power tools for working on cars.

Cordless Polisher/Buffer: Achieving a Flawless Finish

Before delving into the benefits of these mechanics’ cordless tools, it’s important to clarify the distinction between a polisher and a buffer:

- A polisher is designed for more aggressive material removal, employing greater friction and abrasives to level paint surfaces and eliminate deeper imperfections.

- A buffer is used for refining and enhancing the clear coat, a gentler process that maximizes shine and achieves a smoother, swirl-free finish.

Car washes, while convenient, can sometimes inflict fine scratches or swirl marks on car paint from abrasive cleaning methods. In such scenarios, a polisher is the first step to rectify these imperfections. Polishers can be either rotary or dual-action (random orbital), each suited for different levels of paint correction, a topic worthy of its own detailed discussion.

For minor scratches, applying a swirl remover to a polishing pad, followed by a pad conditioner, allows for even polish distribution across the affected area. Polishing with side-to-side or overlapping motions refines the paint surface. Ultimately, using a cordless polisher achieves a deep, lustrous finish that surpasses the original paint appearance.

The cordless advantage in polishers provides comparable power with greater operational freedom. No need to hunt for power outlets or manage tangled cords. This ease of use and portability makes the cordless polisher an invaluable power tool for working on cars, especially for detailing and paint correction tasks where maneuverability is key.

Cordless Heat Gun: Versatile for Wrapping and More

Have you considered car wrapping? It’s not gift wrapping, but rather a transformative method to give your vehicle a fresh look and protect its original paint. Car wrapping presents a cost-effective alternative to traditional and often complex paint jobs. The process requires a clean, prepped car, vinyl film, a precision blade, a squeegee for application, and, crucially, a reliable heat gun.

Among the essential cordless tools for mechanics, a powerful heat gun is needed to apply vinyl wrap. The heat gun softens the plastic vinyl coating, allowing it to conform and adhere smoothly over the vehicle’s painted surfaces. While corded heat guns are common in professional vehicle wrapping centers due to their sustained power for lengthy wrapping projects, cordless heat guns offer distinct advantages. For confined spaces and intricate areas, a cordless heat gun is indispensable. Their lighter weight and improved ergonomics reduce user fatigue during extended use. This portability and ease of handling make cordless heat guns vital power tools for working on cars, particularly for detailed wrapping work, shrink tubing applications, or even thawing frozen locks and lines in colder climates.

Related Article : Best Cordless Tools for Every Field and Task Out There

Pros and Cons of Cordless Tools for Mechanics

Now that we’ve covered the essential cordless tools for mechanics, let’s summarize their advantages and disadvantages in the table below:

| Disadvantages | Advantages | Tool |

|---|---|---|

| Requires periodic battery recharging. Some models can generate noise. | High torque for efficient fastening and loosening. Portability and flexibility for use in diverse locations. Ergonomic designs reduce user fatigue. | Cordless Impact Wrench |

| Limited battery runtime. Noise and potential sparks. Safety considerations with rotating discs. | Versatility across applications. Increased mobility and access. Useful in tight spaces. Quick and easy tool changes. Adjustable speed settings. | Cordless Angle Grinder |

| Lower power and cutting depth compared to larger corded tools. Requires frequent battery changes for extended use. Not ideal for heavy-duty applications. May produce vibrations during operation. | Compact and lightweight for detailed and intricate work. Easy to handle and control. Quick accessory changes. | Cordless Rotary Tool |

| May require a range of pads and compounds for various polishing tasks. | High mobility and freedom of movement. Ergonomic design minimizes user fatigue. Well-suited for automotive detailing and paint correction. | Cordless Polisher |

| May not reach the high temperatures of industrial corded models. Limited heat output compared to high-powered corded heat guns. | Adjustable temperature settings for varied applications. Rapid warm-up times for quick use. | Cordless Heat Gun |

Cordless Power Tools for Car (Automotive) Mechanics: Enhancing Efficiency

Cordless power tools are indispensable for today’s car mechanics, providing the essential flexibility and mobility demanded in fast-paced repair environments. Tools like cordless impact wrenches effortlessly manage tire rotations and brake jobs, while cordless ratchets offer precise control in confined engine bays and interiors. Cordless drills and drivers are versatile for a myriad of drilling, fastening, and component installation tasks, streamlining routine maintenance procedures. Battery-powered impact drivers excel at rapid and accurate screw and bolt driving, accelerating assembly and disassembly processes. These mechanics’ cordless tools not only optimize workflow efficiency for car mechanics but also introduce the agility necessary for effective automotive repairs and preventative maintenance.

Essential Cordless Power Tools for Professional Mechanics

Professional mechanics and automotive repair beginners have different needs when selecting cordless power tools. For seasoned professionals, high-torque cordless impact wrenches are crucial for efficiently tackling heavy-duty tasks like suspension work and transmission repairs. Furthermore, advanced diagnostic scanners with wireless connectivity are vital for pinpointing and resolving complex electronic system faults in modern vehicles. Professional mechanics often invest in comprehensive cordless tools for mechanics sets, encompassing ratchets, drills, grinders, and specialized tools, all contributing to a streamlined workflow and enhanced productivity in a professional garage setting.

Cordless Power Tools for Beginner Mechanics: Starting Smart

Beginner mechanics can effectively start with more versatile and budget-friendly cordless tools. A mid-torque cordless impact wrench offers ample power for most common automotive tasks without the premium price of professional-grade models. A fundamental cordless drill/driver set provides the versatility required for numerous drilling and fastening tasks, making it an excellent entry-level tool for those new to automotive work. As beginners gain experience and expand their skills, they can progressively build their tool collection with additional cordless tools like ratchets, angle grinders, and polishers, tailoring their toolkit to their evolving needs and project demands.