Obd2 Scan Codes are essential for understanding and maintaining vehicle health. These codes, generated by a vehicle’s onboard diagnostic system, provide valuable insights into potential problems within various systems, from the engine to the transmission. This comprehensive guide explores OBD2 scan codes, their types, how to read them, and best practices for managing them for individual vehicle owners and fleet managers.

Decoding OBD2 Scan Codes: Types and Meanings

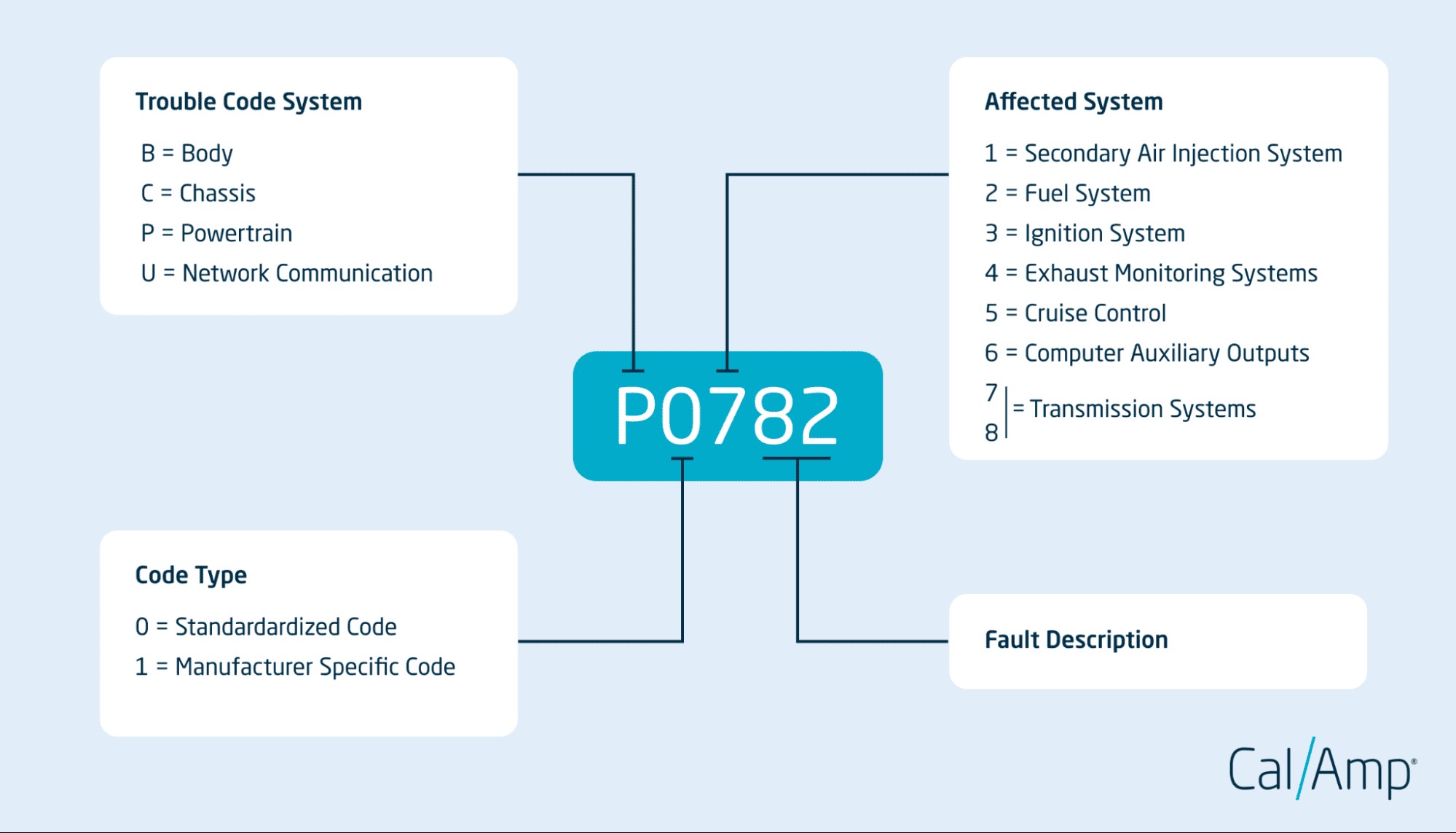

OBD2 scan codes consist of a five-character alphanumeric sequence, each part providing specific information about the issue:

- Trouble Code System: The first letter (P, C, B, U) indicates the system related to the problem:

- P: Powertrain (engine, transmission, emissions)

- C: Chassis (suspension, steering, brakes)

- B: Body (airbags, lighting, climate control)

- U: Network Communication (modules, sensors)

- Code Type: The second character (0 or 1) signifies whether the code is generic (0) or manufacturer-specific (1).

- Affected System: The third character (a number) designates the specific system affected (e.g., fuel system, ignition system).

- Specific Code: The last two digits pinpoint the exact problem within the affected system.

Understanding this structure allows for a quick assessment of the problem area.

What OBD2 codes mean

What OBD2 codes mean

Common Types of OBD2 Trouble Codes

Several common types of OBD2 scan codes frequently appear:

- P0101 (MAF Sensor): Indicates a problem with the Mass Air Flow sensor, affecting fuel efficiency and engine performance.

- B0020 (Airbag): Signals an issue with the driver’s side airbag deployment circuit, posing a safety risk.

- C1234 (Wheel Speed Sensor): Points to a malfunctioning wheel speed sensor, impacting vehicle stability and braking systems.

- U0100 (ECM Communication): Suggests a communication breakdown with the Engine Control Module, often caused by a faulty battery.

Reading and Clearing OBD2 Scan Codes

Reading OBD2 scan codes requires an OBD2 scanner, a device that connects to the vehicle’s OBD2 port (usually located under the dashboard). The scanner retrieves diagnostic trouble codes (DTCs), providing insights into the issue.

Clearing codes can be done with a scanner, through a specific drive cycle, or by a mechanic. However, clearing codes without addressing the underlying problem is not recommended.

Preventing OBD2 Scan Codes

Proactive measures can prevent OBD2 scan codes and maintain vehicle health:

-

Regular Maintenance: Routine inspections, fluid changes, and timely repairs prevent small issues from escalating. Adhering to the manufacturer’s recommended maintenance schedule is crucial.

-

Quality Fuel and Fluids: Using high-quality fuel and fluids ensures proper lubrication and combustion, reducing the risk of codes related to engine performance and emissions. Regularly checking fluid levels is essential.

Managing OBD2 Scan Codes for Fleets

For fleet management, efficient handling of OBD2 scan codes is crucial:

-

Centralized Code Tracking: Consolidating OBD2 data from all vehicles into a single system allows for easy access, analysis, and identification of recurring issues.

-

Ongoing Fleet Monitoring: Real-time monitoring using telematics systems enables immediate detection of OBD2 codes, facilitating prompt repairs and minimizing downtime.

-

Prioritized Repairs: Categorizing codes based on severity ensures that critical issues are addressed first, optimizing resource allocation and maintaining fleet operations.

Conclusion

OBD2 scan codes are invaluable for vehicle diagnostics, providing critical information for maintenance and repair. Understanding these codes empowers vehicle owners and fleet managers to address potential problems proactively, minimizing downtime and ensuring optimal vehicle performance. Utilizing advanced fleet management solutions, like CalAmp, can streamline the process of monitoring and managing OBD2 codes, leading to improved efficiency and cost savings.