OBD2, or On-Board Diagnostics, is a vehicle’s self-diagnostic system. A crucial component of OBD2 is the CAN ID, which allows for communication between the vehicle’s electronic control units (ECUs) and diagnostic tools. This article delves into the intricacies of Obd2 Can Id, covering its structure, functionality, and practical applications.

What is OBD2 CAN ID?

OBD2 relies heavily on the Controller Area Network (CAN) bus for communication. Each message transmitted on the CAN bus has a unique identifier, the CAN ID. This ID dictates the message priority and the intended recipient ECU. Within the context of OBD2, specific CAN IDs are reserved for diagnostic requests and responses, enabling standardized communication with external diagnostic tools.

How OBD2 Leverages CAN Bus

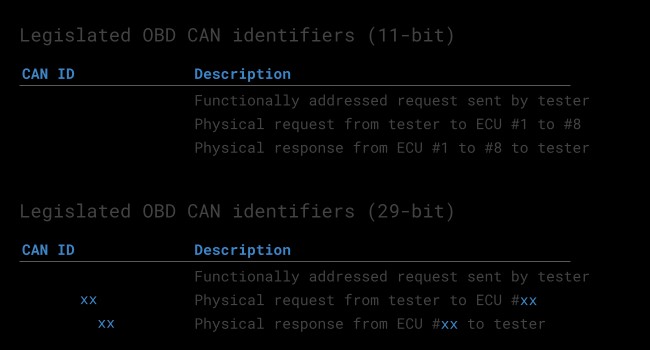

Since 2008, all US cars have mandated CAN bus as the underlying communication protocol for OBD2, as defined by ISO 15765. This standard specifies the use of either 11-bit or 29-bit CAN IDs for OBD2 communication.

11-bit CAN IDs in OBD2

Most passenger cars utilize 11-bit CAN IDs for OBD2. A ‘Functional Addressing’ request, using CAN ID 0x7DF, broadcasts a request to all compatible ECUs. Responses from these ECUs typically use CAN IDs 0x7E8-0x7EF.

29-bit CAN IDs in OBD2

Larger vehicles, such as vans and trucks, often employ 29-bit CAN IDs. The ‘Functional Addressing’ request ID in this case is 0x18DB33F1, with responses utilizing CAN IDs ranging from 0x18DAF100 to 0x18DAF1FF.

OBD2 Request and Response Structure using CAN IDs

OBD2 communication follows a request-response pattern. A diagnostic tool sends a request message with a specific CAN ID and data payload containing the desired mode and Parameter ID (PID). The targeted ECU responds with a message containing the requested data, using a designated response CAN ID.

Decoding OBD2 Data with CAN IDs

Decoding the raw data within OBD2 messages requires knowledge of the CAN ID, mode, and PID. This information, combined with standardized scaling rules, allows for the conversion of raw data into meaningful physical values like speed, engine RPM, and fuel level. DBC (Database CAN) files provide a structured way to define these decoding rules, facilitating automated data interpretation.

Practical Applications of OBD2 CAN ID

Understanding OBD2 CAN ID is crucial for various applications:

- Vehicle Diagnostics: Identifying and troubleshooting vehicle issues using diagnostic scanners.

- Data Logging: Recording vehicle data for performance monitoring, fleet management, and predictive maintenance.

- Real-time Monitoring: Streaming live vehicle data for driver feedback or remote diagnostics.

- Security and Hacking Prevention: Analyzing CAN traffic for anomalies and potential security breaches.

Conclusion

OBD2 CAN ID plays a fundamental role in vehicle diagnostics and data analysis. A thorough understanding of its structure and functionality is essential for anyone working with vehicle data, from mechanics to fleet managers to automotive engineers. By leveraging the standardized communication enabled by OBD2 CAN ID, valuable insights into vehicle performance, health, and behavior can be obtained. Tools and resources like DBC files and specialized software further simplify the process of decoding and analyzing this data, unlocking its full potential for a wide range of applications.