The Obd Obd2 Connector, short for On-Board Diagnostics, is a standardized 16-pin port found in most vehicles manufactured after 1996. It serves as a vital interface for accessing a vehicle’s diagnostic trouble codes (DTCs) and real-time performance data. This article delves into the intricacies of the OBD OBD2 connector, exploring its history, standards, pinout configuration, and its crucial role in modern vehicle diagnostics.

A Brief History of OBD2

The California Air Resources Board (CARB) initially mandated OBD systems in 1991 to monitor emissions. This evolved into the OBD2 standard, recommended by the Society of Automotive Engineers (SAE) and standardized under SAE J1962. OBD2 ensures consistent DTCs and connector configurations across all vehicle manufacturers.

The implementation of OBD2 was a gradual process:

- 1996: Mandatory for cars and light trucks in the USA.

- 2001: Mandatory for gasoline cars in the EU.

- 2003: Extended to diesel cars in the EU (EOBD).

- 2008: ISO 15765-4 (CAN) became the required communication protocol for OBD2 in the US.

OBD2 Connector Pinout: Decoding the 16 Pins

The OBD OBD2 connector, typically located near the steering wheel, provides access to a wealth of vehicle data through its 16 pins. Each pin has a specific function, facilitating communication between the vehicle’s electronic control units (ECUs) and diagnostic tools.

Key pin functions include:

- Pin 2: J1850 Bus+

- Pin 4: Chassis Ground

- Pin 5: Signal Ground

- Pin 6: CAN High (CAN-H)

- Pin 7: ISO 9141-2 K-Line

- Pin 10: J1850 Bus-

- Pin 14: CAN Low (CAN-L)

- Pin 15: ISO 9141-2 L-Line

- Pin 16: Battery Power

OBD2 and CAN Bus: The Language of Modern Vehicles

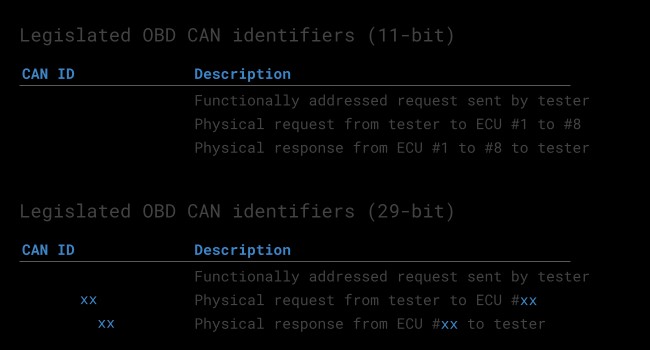

Since 2008, Controller Area Network (CAN bus) has been the mandated communication protocol for OBD2 in the US. ISO 15765-4 specifies the use of CAN for transmitting diagnostic data. Key aspects of this standard include defined CAN identifiers (IDs) for requests and responses, a standardized 8-byte data length for diagnostic frames, and specified bit rates of 250K or 500K.

OBD2 CAN Identifiers

OBD2 CAN Identifiers

OBD2 Standards: Ensuring Compatibility and Consistency

OBD2 relies on several standards to ensure seamless communication and data interpretation across different vehicle makes and models. These standards define various aspects, including communication protocols, diagnostic modes, and parameter IDs (PIDs).

Key OBD2 Standards:

- SAE J1979/ISO 15031-5: Defines diagnostic message format and modes.

- ISO 15765-2: Specifies the ISO-TP transport protocol for managing data packets larger than 8 bytes.

- SAE J1962/ISO 15031-3: Standardizes the physical characteristics of the OBD OBD2 connector.

Beyond the Basics: The Future of OBD2

While OBD2 remains a cornerstone of vehicle diagnostics, the automotive industry is constantly evolving. Trends like the increasing prevalence of electric vehicles (EVs) and the rise of connected car technologies are shaping the future of OBD. New protocols like WWH-OBD and OBDonUDS aim to enhance diagnostic capabilities and leverage the UDS protocol.

Conclusion: The OBD OBD2 Connector – An Essential Tool

The OBD OBD2 connector is an indispensable tool for anyone involved in vehicle maintenance and repair. Understanding its functionality and the underlying standards is crucial for effectively diagnosing and resolving vehicle issues. As vehicle technology continues to advance, the OBD OBD2 connector will undoubtedly remain a vital component in the automotive ecosystem.