The OBD2 (On-Board Diagnostics) system is your vehicle’s self-diagnostic tool, providing crucial insights into its performance and health. A key component of this system is the OBD2 connector, and for RAM 700 owners, understanding this interface is essential. This comprehensive guide explores the OBD2 connector specifically for the RAM 700, covering its functionality, location, compatibility, and potential uses.

Understanding the OBD2 System in Your RAM 700

The OBD2 system in your RAM 700 continuously monitors various engine and emission-related components. When an issue is detected, the system stores a Diagnostic Trouble Code (DTC) and may illuminate the Malfunction Indicator Lamp (MIL) on your dashboard, often referred to as the “check engine” light. Accessing this information requires connecting to the OBD2 port, typically located under the dashboard on the driver’s side. Using an OBD2 scanner or code reader, you can retrieve these codes, providing valuable clues for troubleshooting.

Locating the OBD2 Connector in Your RAM 700

The OBD2 connector in the RAM 700 is usually found beneath the steering wheel, near the fuse box. It’s a standardized 16-pin connector, often referred to as the Data Link Connector (DLC). While generally easy to access, its exact location might vary slightly depending on the model year. Consulting your owner’s manual can pinpoint its precise position. The connector is typically female and trapezoidal in shape, ensuring a secure connection with compatible diagnostic tools.

Compatibility and Protocols of the RAM 700 OBD2 Connector

The RAM 700, like most modern vehicles, adheres to the ISO 15765-4 standard, utilizing CAN (Controller Area Network) as the primary communication protocol for OBD2. This protocol governs how data is transmitted between the vehicle’s ECUs (Electronic Control Units) and the diagnostic tool. The standard baud rate for the RAM 700 is typically 500 Kbps. However, some models may use 250 Kbps. It’s important to confirm the specific baud rate for your RAM 700’s model year to ensure proper communication with diagnostic equipment.

Utilizing the OBD2 RAM 700 Connector: Beyond Diagnostics

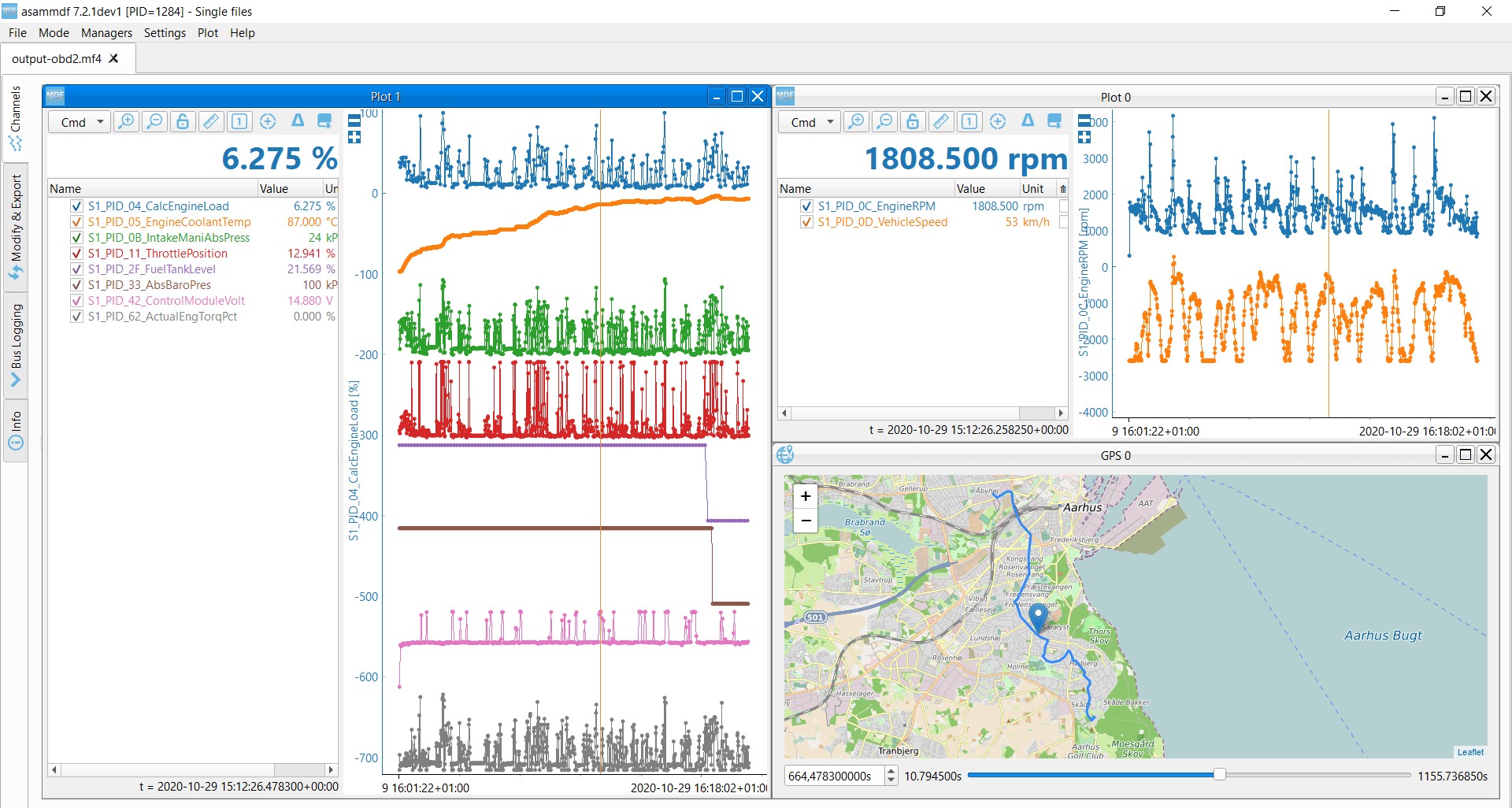

The OBD2 connector offers more than just diagnostic capabilities. It opens a gateway to a wealth of real-time data, including:

- Vehicle Speed: Monitor your current speed for performance tracking or driver behavior analysis.

- Engine RPM: Track engine revolutions per minute for insights into engine performance.

- Fuel Consumption: Analyze fuel economy and identify potential inefficiencies.

- Coolant Temperature: Monitor engine temperature to prevent overheating.

This data can be accessed using various OBD2 tools, ranging from basic code readers to advanced data loggers and smartphone apps.

OBD2 Data Logging and Analysis

OBD2 Data Logging and Analysis

Advanced Applications with the OBD2 RAM 700 Connector

Beyond basic diagnostics and data monitoring, the OBD2 connector can be leveraged for advanced applications:

- Fleet Management: Track vehicle location, performance, and driver behavior for optimized fleet operations.

- Performance Tuning: Monitor and adjust engine parameters for enhanced performance.

- Insurance Telematics: Utilize data for usage-based insurance programs.

- Predictive Maintenance: Analyze data trends to anticipate potential maintenance needs and prevent breakdowns.

Conclusion: Harnessing the Power of OBD2 in Your RAM 700

The OBD2 connector in your RAM 700 is a powerful tool, offering a wealth of information about your vehicle’s health and performance. Understanding its functionality and potential applications empowers you to take control of your vehicle’s maintenance, optimize its performance, and even contribute to cost savings through informed decisions. From simple diagnostics to advanced data analysis, the OBD2 RAM 700 connector unlocks a world of possibilities for both individual owners and fleet managers.