In the fast-paced world of automotive repair, efficiency and precision are paramount. Every car mechanic knows that having the right tools can make all the difference between a job done well and a job done poorly. While traditional corded power tools have long been a staple in auto shops, the rise of cordless Power Tools For Car Mechanics has revolutionized the industry. These battery-powered marvels offer unparalleled freedom and flexibility, allowing mechanics to move around the vehicle and the workshop with ease. This article will delve into the essential cordless power tools that every car mechanic, from seasoned professional to eager beginner, should consider for a fully equipped and modern garage.

Cordless Power Tools for Mechanics

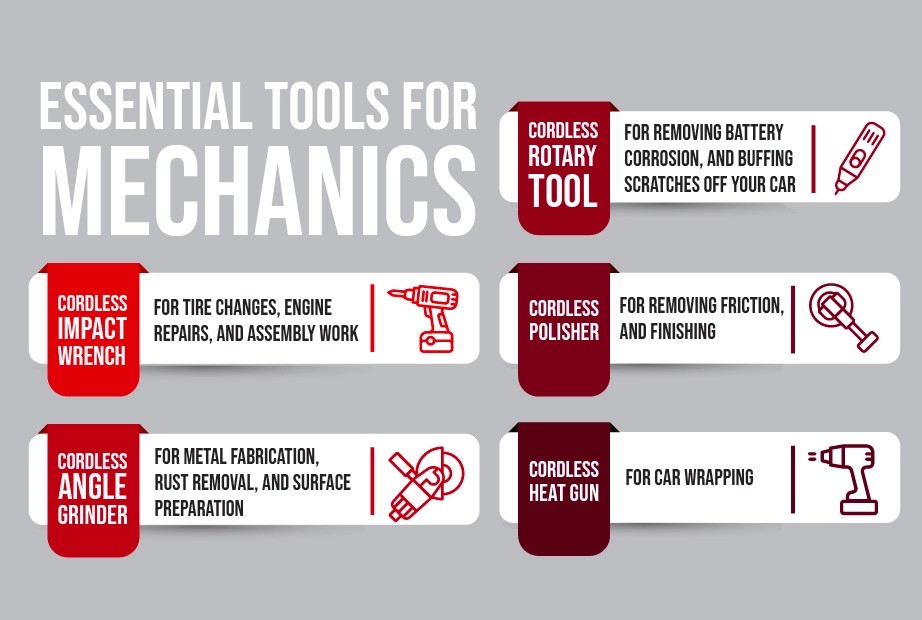

Mechanics’ cordless tools are incredibly versatile and find applications across a wide spectrum of tasks. From pinpointing complex engine problems to executing intricate repairs and conducting routine vehicle maintenance, cordless tools are indispensable. Their utility extends beyond just cars, encompassing motorcycles, heavy-duty industrial machinery, aircraft, and much more. The specific power tools for mechanics that are considered “essential” can vary depending on the mechanic’s specialization and the demands of their work. However, certain cordless tools consistently prove their value in almost any automotive repair setting. Let’s explore some of the most commonly essential cordless power tools that can significantly enhance a mechanic’s toolkit.

Essential Cordless Power Tools for Your Auto Repair Shop

Cordless Impact Wrench

The cordless impact wrench is arguably the king of power tools for car mechanics. Walk into virtually any auto repair shop, and you’re guaranteed to find one, if not several, of these powerful tools. Designed for situations demanding high torque, an impact wrench, paired with a comprehensive socket set, becomes indispensable. Its primary function? Effortlessly loosening and tightening stubborn lug nuts on cars, trucks, and various machinery. It’s easy to confuse an impact wrench with an impact driver, but there are key differences. A standard impact wrench is designed to accommodate ½-inch sockets, capable of handling the large sizes needed for wheel lugs. In contrast, an impact driver typically features a ¼-inch hex opening, meant for smaller fasteners.

Before cordless technology dominated the scene, pneumatic impact wrenches, powered by compressed air, were the industry standard in professional garages. However, advancements in battery technology have dramatically improved cordless impact wrenches. They now offer comparable power, reduced prices, and, crucially, unmatched portability, making them a compelling alternative to their pneumatic predecessors. The freedom of movement offered by these mechanics’ power tools is a game-changer. Mechanics can navigate around a vehicle unencumbered by air hoses or power cords, loosening lug nuts quickly and efficiently, a benefit particularly valuable in busy workshops.

Cordless Angle Grinder

While perhaps not always visible at first glance in every garage, the cordless angle grinder is a remarkably versatile tool that proves its necessity in numerous car repair situations. An angle grinder is composed of several key components: a high-speed spinning wheel for cutting, grinding, and polishing, a protective safeguard, and a robust housing. One of the most common uses for an angle grinder in auto repair is removing rust and old paint from vehicle components. Different sizes and types of grinding wheels can be used to achieve precise results for various rust removal tasks, from surface corrosion to more extensive rust damage.

Beyond rust removal, the angle grinder’s metal-cutting prowess is invaluable. Mechanics use it to cut through metal sheets, such as sections of car bodies needing repair or replacement. The portability of a cordless angle grinder provides enhanced control during these cutting and grinding operations, allowing for greater precision and maneuverability, especially in awkward or confined spaces under a vehicle or within the engine bay.

Cordless Rotary Tool

Among the array of cordless mechanic tools, the rotary tool might initially seem too delicate for the robust tasks of vehicle repair. However, this compact tool is surprisingly versatile and highly efficient for a multitude of detailed jobs that arise frequently in auto mechanics. Consider tasks like removing battery corrosion – far more effectively and precisely done with a rotary tool than with a basic toothbrush. Or imagine cutting through a rusted clamp in a tight engine compartment; a rotary tool excels where larger tools struggle.

Furthermore, a cordless rotary tool is excellent for cosmetic vehicle care. It can be used to buff out minor scratches on cars, trucks, RVs, or motorcycles. The process typically involves cleaning the scratched area, applying a rubbing compound with a felt wheel attachment in a circular motion to smooth out imperfections. After the compound dries, it’s easily removed with a soft microfiber cloth, followed by the application of a polishing compound, again using circular motions. This detailed approach, achievable with a rotary tool and various specialized wheels, can significantly restore a vehicle’s appearance. The cordless nature of the tool enhances control and allows mechanics to work in diverse positions without being restricted by a power cord.

Cordless Polisher/Buffer

Before discussing the advantages of mechanics’ cordless tools in polishing and buffing, it’s important to clarify the distinction between a polisher and a buffer. A polisher is designed for more aggressive paint correction tasks. It operates with more friction and often uses abrasive compounds to level out paint imperfections, such as deeper scratches or swirl marks. A buffer, on the other hand, is used for gentler applications, primarily to refine and enhance the clear coat, bringing out maximum shine and a smoother, more lustrous finish.

Car washes, while convenient, can sometimes inflict minor paint damage. Aggressive scrubbing with abrasive materials like Scotch-Brite pads or brillo pads can leave unsightly swirl marks on car paint. In such cases, a polisher is the necessary first step to correct these imperfections. Polishers can be either rotary or dual-action, each with its own set of characteristics and applications (a topic worthy of its own dedicated discussion). For minor scratches, simply applying a swirl remover to a polishing pad, spraying a pad conditioner, and then working the polisher side-to-side over the scratch can produce remarkable results. The final buffing stage then brings out a deep, showroom-quality shine that dramatically improves the vehicle’s appearance compared to its original, scratched condition. A cordless polisher offers the same power as corded models but with significantly greater convenience. The freedom from power outlets and tangled cords streamlines the polishing process, making it more efficient and less cumbersome.

Cordless Heat Gun

Have you ever considered car wrapping? It’s not about gift presentation, but about transforming the look of your vehicle and protecting its paintwork simultaneously. Car wrapping provides an alternative to traditional repainting, offering a new aesthetic without the extensive and costly process of spraying new color. The essentials for car wrapping include a clean and prepared car surface, a vinyl film in your desired color or finish, a sharp blade for trimming, a squeegee for application, and crucially, a reliable heat gun.

Among essential cordless tools for mechanics, a powerful heat gun is vital for car wrapping. It’s used to apply a plastic vinyl coating to the vehicle’s body panels. The heat softens the vinyl, allowing it to conform to the complex curves and shapes of the car and adhere securely to the paintwork. While corded heat guns are often the standard in professional vehicle wrapping centers due to their consistent power output for lengthy jobs, cordless heat guns offer significant advantages, especially in specific situations. Vehicle wrapping is a time-consuming process, and battery life can be a concern for large projects. However, for confined spaces, intricate detailing work, or quick touch-ups during wrapping, a cordless heat gun is invaluable. Their lighter weight and ease of handling also reduce user fatigue, making them more comfortable for extended use, particularly in challenging positions.

Related Article : Best Cordless Tools for Every Field and Task Out There

Pros and Cons of Cordless Tools for Mechanics

Cordless tools bring a wealth of advantages to the auto mechanic’s workspace, but like all tools, they also have limitations. The table below summarizes the key pros and cons of the cordless power tools discussed.

| Disadvantages | Advantages | Tool |

|---|---|---|

| Requires periodic battery recharging. Some models may be noisy. | High torque for efficient fastening and loosening. Portability and flexibility for use in various locations. Reduced user fatigue with ergonomic designs. | Cordless Impact Wrench |

| Limited battery life. Noise and sparks. Safety concerns with rotating discs. | Versatility. Increased mobility. Useful in tight spaces. Quick and easy tool changes. Adjustable speed. | Cordless Angle Grinder |

| Limited power and cutting depth compared to larger tools. Requires frequent recharging. Not suitable for heavy-duty tasks. May produce vibrations. | Compact and lightweight for detailed work. Easy to work with. Quick tool changes. | Cordless Rotary Tool |

| May require additional accessories for different polishing applications. | High mobility. Ergonomic for reduced user fatigue. Suitable for automotive detailing. | Cordless Polisher |

| May not reach the high temperatures of corded models. Limited heat output compared to corded industrial heat guns. | Adjustable temperature settings. Quick warm-up times. | Cordless Heat Gun |

Cordless Power Tools for Car (Automotive) Mechanics

Cordless power tools for car mechanics are not just a convenience; they are a necessity in modern automotive repair. They provide the flexibility and mobility crucial for thriving in fast-paced repair environments. Consider tire changes: cordless impact wrenches make quick work of lug nuts, significantly reducing downtime. In tight engine compartments or under dashboards, cordless ratchets offer the precise control needed for intricate fastening tasks. Cordless drills and drivers are versatile workhorses, handling drilling and fastening operations efficiently across routine maintenance and complex repairs. Battery-powered impact drivers excel at quickly and accurately driving screws and bolts, speeding up both assembly and disassembly processes. These mechanics’ cordless tools streamline workflows, enhance agility, and are essential for effective and efficient automotive repairs and maintenance.

Essential Cordless Power Tools for Professional Mechanics

Professional mechanics and those just starting out in automotive work have different needs when it comes to cordless tools for mechanics. For seasoned professionals, high-torque cordless impact wrenches are indispensable for tackling demanding jobs like frequent tire changes and heavy-duty repairs. Furthermore, advanced diagnostic scanners with wireless capabilities become critical for diagnosing and resolving the increasingly complex electronic systems in modern vehicles. Professional mechanics often invest in comprehensive sets of cordless tools for mechanics, including ratchets, drills, grinders, and more, all contributing to a seamless and highly efficient workflow in a professional garage setting.

Cordless Power Tools for Beginner Mechanics

For those new to automotive mechanics, starting with versatile and more budget-friendly cordless tools is a smart approach. A mid-range cordless impact wrench provides ample torque for most common tasks without the higher price tag of professional-grade models. A basic cordless drill/driver is an excellent starting point, offering the versatility needed for a wide array of drilling and fastening jobs – ideal for beginners learning the ropes of auto repair. As beginners gain experience and refine their skills, they can gradually expand their tool collection, adding other valuable cordless tools like ratchets and angle grinders as their needs evolve and their expertise grows.