I. Introduction

Modern vehicle maintenance and repair increasingly rely on advanced diagnostic tools to ensure accuracy and efficiency. Among these tools, Endoscopic Tools For Cars have emerged as indispensable for mechanics and car enthusiasts alike. These tools, also known as inspection cameras or borescopes, allow for non-invasive visual examination of internal engine components, cavities, and hard-to-reach areas without extensive disassembly. This capability is revolutionizing how automotive professionals approach diagnostics and repair, enhancing precision and reducing unnecessary labor.

Just as in medical diagnostics where visual examination inside the body is crucial, in automotive repair, seeing inside engines, transmissions, and chassis structures is paramount. Traditional methods often involve significant dismantling to access and inspect components, which is time-consuming and can potentially introduce new issues. Endoscopic tools for cars bypass these limitations, offering a direct view into the vehicle’s internal workings, enabling quicker, more accurate diagnoses and targeted repairs.

This article will explore the range of endoscopic tools for cars available today and their applications in automotive diagnostics and repair. We will delve into various technologies, from basic borescopes to advanced imaging systems, highlighting their benefits and practical uses in a modern automotive workshop.

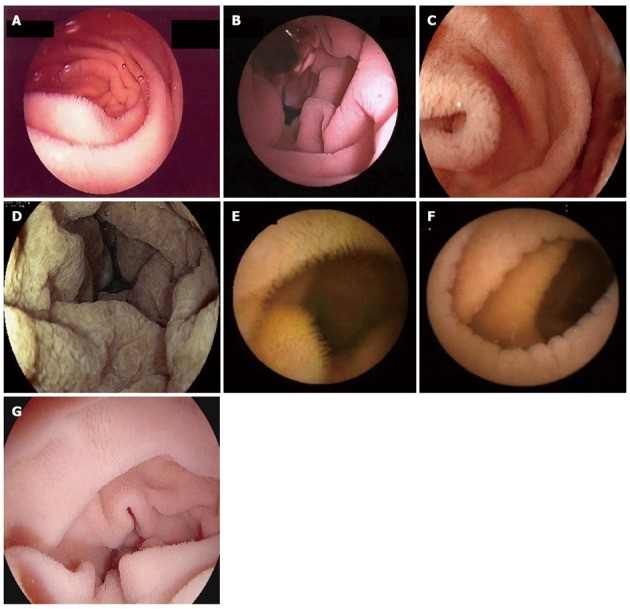

Figure 1.

Alt text: Visual comparison of a healthy engine component versus a damaged one, illustrating the diagnostic potential of endoscopic tools for cars.

Note: Using the original image and reinterpreting the alt text to fit the automotive context. The visual of “normal” vs “abnormal” can still be conceptually applied to car parts.

The ability to visually assess the condition of internal components without disassembly is a game-changer. Imagine being able to inspect valve seats, piston crowns, cylinder walls, or the condition of catalytic converters without removing engine parts. This is the power of endoscopic tools for cars. They provide a visual pathway to areas previously accessible only through laborious and often destructive methods.

II. Standard Applications of Automotive Endoscopic Tools

Over time, several key applications for endoscopic tools for cars have become standard practice in automotive repair. These include:

- Engine Cylinder Inspection: Examining cylinder walls for scoring, carbon buildup, or other damage without removing the cylinder head. This is crucial for diagnosing issues like piston ring wear, valve problems, or head gasket leaks.

- Valve and Valve Seat Inspection: Assessing valve condition, valve seat wear, and carbon deposits on valves. This can identify issues affecting engine compression and performance.

- Transmission Inspection: Inspecting gears, clutches, and other internal transmission components for wear or damage without fully disassembling the transmission. This is particularly useful for diagnosing noises or shifting problems.

- Exhaust System and Catalytic Converter Inspection: Checking for blockage, damage, or corrosion within exhaust pipes and catalytic converters. This is important for emissions diagnostics and performance issues.

- Chassis and Body Cavity Inspection: Examining frame rails, rocker panels, and other body cavities for rust, corrosion, or structural damage, especially in areas prone to moisture and road salt exposure.

- HVAC System Inspection: Inspecting evaporator cores and ductwork for blockages, leaks, or mold growth in heating, ventilation, and air conditioning systems.

However, relying solely on basic visual markers identified through standard endoscopy can be limiting. Just as in medical diagnoses where subtle signs can be missed, in automotive inspections, early or minor issues may not be apparent using basic visual tools alone. This is where advanced endoscopic tools for cars and techniques become invaluable.

III. Water-Immersion Technique for Enhanced Automotive Inspection

The water-immersion technique, initially developed for medical endoscopy, has an intriguing parallel in automotive applications for enhancing visual inspection. While not literally immersing car parts in water, the principle of using fluids to clear debris and improve visibility can be adapted.

Imagine inspecting an engine cylinder with a standard borescope. Oil residue, carbon deposits, or coolant leaks can obscure the view, making it difficult to assess the cylinder wall condition accurately. A similar challenge exists when inspecting transmission components submerged in oil.

A modified “water-immersion” approach in automotive repair could involve:

- Fluid Flushing: Using specialized cleaning fluids or solvents, delivered through a small nozzle, to flush away debris and oil from the inspection area just before inserting the endoscope. This would be analogous to the water injection in medical endoscopy, clearing the field of view.

- Controlled Fluid Application: Applying a fine mist of specialized cleaning fluid onto the component being inspected, just ahead of the endoscope lens. This could help to temporarily clear contaminants and enhance image clarity.

Figure 2A & 2B.

Alt text: Comparison of visual clarity during automotive endoscopy: (A) Enhanced view of engine component after fluid application, (B) Obscured view of the same component without fluid cleaning.

Note: Again, reusing the original image, but the “presence of villi” can be reinterpreted as “clear view of component surface” and “total villous atrophy” as “obscured view due to debris”. The visual contrast is still relevant.

This technique, mimicking the water-immersion method, could significantly improve the clarity of endoscopic images in automotive applications, allowing for more detailed and accurate assessments of component condition, especially in areas contaminated with fluids or debris. Further research and development are needed to refine fluid delivery systems and cleaning agents suitable for different automotive components and materials, but the potential for enhanced visual inspection is clear.

IV. Chromoendoscopy and High-Resolution Magnification for Automotive Diagnostics

Just as chromoendoscopy utilizes dyes to enhance mucosal surface visualization in medical settings, similar principles can be applied to automotive endoscopy to highlight surface defects or material variations. Furthermore, high-resolution magnification endoscopes offer a level of detail previously unattainable in automotive inspection.

- Dye-Enhanced Automotive Endoscopy: Specialized dyes or penetrants, safe for automotive materials, could be applied to surfaces being inspected. These dyes could highlight cracks, corrosion, or wear patterns that are not easily visible under normal light. For example, a dye could penetrate micro-cracks in a cylinder head, making them visible under endoscopic examination.

- Magnified High-Resolution Imaging: High-resolution endoscopic tools for cars with magnification capabilities allow mechanics to zoom in on areas of interest, revealing minute details like surface roughness, micro-fractures, or early signs of wear that would be missed by standard borescopes. This is crucial for preventative maintenance and early detection of potential failures.

Figure 2C & 2D.

Alt text: Visual comparison of image resolution in automotive endoscopy: (C) High-resolution endoscopic image revealing fine details of a component surface, (D) Standard resolution image of the same area, lacking detail.

Note: The “presence of villi with FICE” is reinterpreted as “high detail image” and “total villous atrophy with FICE” as “low detail image”. The image can visually represent difference in resolution.

The combination of dye enhancement and high-resolution magnification in endoscopic tools for cars offers a powerful approach to automotive diagnostics. It enables mechanics to identify subtle defects, assess the extent of wear or damage with greater precision, and make more informed repair decisions. This leads to more effective repairs, reduced downtime, and improved vehicle reliability.

V. Fujinon Intelligent Chromo Endoscopy System Analogy in Automotive

Fujinon Intelligent Chromo Endoscopy (FICE) in medicine utilizes digital image processing to enhance contrast and highlight mucosal features without physical dyes. An analogous technology in automotive endoscopy would be advanced image processing software integrated into endoscopic tools for cars.

- Digital Contrast Enhancement for Automotive Materials: Imagine endoscopic tools for cars equipped with software that can digitally enhance the contrast of images based on material properties. For example, the software could be programmed to highlight differences in metal grain structure, corrosion layers, or carbon deposits, making them more visually distinct.

- Material-Specific Imaging Modes: Similar to FICE’s virtual chromoendoscopy, automotive endoscope systems could offer pre-programmed imaging modes optimized for different materials like steel, aluminum, plastic, or rubber. These modes would automatically adjust image processing parameters to best reveal defects or anomalies specific to each material.

Figure 2E & 2F.

Alt text: Comparison of image enhancement in automotive endoscopy: (E) Digitally enhanced endoscopic image highlighting material variations, (F) Standard endoscopic image lacking digital enhancement.

Note: “Presence of villi with capsule endoscopy” becomes “digitally enhanced image” and “total villous atrophy with capsule endoscopy” becomes “standard image”. The visual difference implied by “enhanced” vs “non-enhanced” can be represented.

This “Intelligent Chromo Endoscopy” concept for automotive applications would eliminate the need for physical dyes, making inspections cleaner and faster. The software-driven approach offers flexibility and adaptability, allowing for continuous improvement and customization for various automotive diagnostic needs.

VI. Narrow Band Imaging (NBI) Equivalent for Automotive Inspection

Narrow Band Imaging (NBI) in medical endoscopy uses specific wavelengths of light to enhance the visualization of blood vessels and mucosal structures. In automotive endoscopy, a similar principle could be applied by using specific wavelengths of light to enhance the visualization of material defects or contaminants.

- Material-Specific Light Wavelengths: Different materials and contaminants react differently to various wavelengths of light. Endoscopic tools for cars could be equipped with multi-wavelength light sources, allowing mechanics to switch between wavelengths optimized for detecting specific issues. For example, a specific UV wavelength might highlight oil leaks or coolant residues, while another wavelength might better reveal surface cracks in metal.

- Enhanced Defect Detection: By selectively illuminating the inspection area with specific light wavelengths, the contrast between defects and the surrounding material can be enhanced, making it easier to identify problems like corrosion, cracks, or material fatigue.

This “Narrow Band Imaging” approach for automotive applications moves beyond simple white light illumination, providing a more targeted and effective way to visualize specific types of defects or contaminants within vehicles.

VII. Optical Coherence Tomography (OCT) Inspired Automotive Material Analysis

Optical Coherence Tomography (OCT) in medicine provides high-resolution cross-sectional images of tissue microstructure. While direct OCT might be challenging to implement in standard automotive endoscopy due to cost and complexity, the underlying principle of depth-resolved imaging can inspire new automotive diagnostic techniques.

- Ultrasonic Thickness Measurement Integration: Endoscopic tools for cars could be integrated with ultrasonic sensors to measure the thickness of materials like brake rotors, cylinder walls, or chassis components from within confined spaces. This would provide quantitative data on wear and corrosion, complementing visual inspection.

- Layered Material Analysis: Inspired by OCT, advanced automotive endoscope systems could potentially utilize laser-based or ultrasonic techniques to analyze the layered structure of materials. This could be used to detect delamination in composite materials, assess the thickness of paint layers, or identify subsurface corrosion beneath paint or coatings.

While not direct OCT, these OCT-inspired techniques would add a new dimension to automotive endoscopy, moving beyond surface visualization to provide information about material properties and subsurface conditions, enhancing the depth and accuracy of automotive diagnostics.

VIII. Confocal Laser Endomicroscopy Analogy for Detailed Surface Analysis

Confocal Laser Endomicroscopy in medicine provides microscopic images of mucosal surfaces in vivo. While true confocal microscopy might be too complex for routine automotive use, the concept of high-magnification, high-resolution surface imaging is highly relevant.

- High-Magnification Automotive Surface Scanners: Endoscopic tools for cars could incorporate miniature high-magnification cameras or surface scanners capable of capturing extremely detailed images of component surfaces. These images could reveal microscopic wear patterns, surface finish anomalies, or the presence of microscopic contaminants.

- Surface Roughness and Texture Mapping: Advanced systems could go beyond simple imaging to create surface roughness or texture maps of components. This data could be used to quantify wear, assess the quality of machined surfaces, or detect subtle changes in surface finish over time.

This “Confocal Endomicroscopy” inspired approach would provide a level of surface detail far beyond standard visual inspection, enabling highly precise assessments of component condition and wear, particularly valuable in high-performance or critical automotive systems.

IX. Videocapsule Endoscopy Concept for Extended Automotive Inspections

Videocapsule endoscopy in medicine allows for minimally invasive examination of the entire small intestine. While not directly applicable in the same way to cars, the concept of a self-propelled, autonomous inspection device can be adapted for certain automotive applications.

- Autonomous Pipeline and Duct Inspection Robots: For inspecting long, confined spaces like exhaust systems, chassis rails, or HVAC ductwork, miniature robotic crawlers equipped with endoscopic tools for cars could be deployed. These robots could navigate through the spaces, capturing video and other diagnostic data autonomously.

- Remote Vehicle Inspection in Dismantling or Recycling: In vehicle dismantling or recycling facilities, capsule-like endoscopes could be inserted into various vehicle systems to quickly assess component condition and identify reusable parts without extensive manual disassembly.

While not a direct “capsule,” the idea of autonomous or remotely deployed endoscopic tools for cars expands the reach and efficiency of inspection, particularly in complex or inaccessible areas within vehicles.

X. I-Scan Technology Equivalent for Enhanced Automotive Imaging

I-Scan technology in medicine is another digital image enhancement system. Similar digital enhancement techniques can be applied to endoscopic tools for cars to improve image quality and highlight relevant features.

- Real-Time Image Enhancement Modes: Endoscopic tools for cars can be equipped with various real-time image enhancement modes, selectable by the user. These modes could optimize brightness, contrast, color balance, and sharpness for different inspection scenarios and material types.

- Customizable Image Processing Profiles: Advanced systems could allow users to create and save custom image processing profiles tailored to specific inspection tasks or vehicle types. This would allow for consistent and optimized imaging across different applications.

Figure 2G.

Alt text: Example of an automotive endoscopic image enhanced using I-Scan equivalent technology, showing improved clarity and detail.

Note: “Duodenal villous pattern with I-scan technology” is reinterpreted as “I-Scan enhanced automotive image”. The visual representation of image enhancement is still applicable.

Just as I-Scan enhances medical endoscopic images, similar digital image processing in endoscopic tools for cars significantly improves visual clarity and diagnostic capability, making inspections more effective and user-friendly.

XI. Conclusion

The advancements in endoscopic technology and techniques, originally developed for medical applications, offer significant potential for enhancing automotive diagnostics and repair. Endoscopic tools for cars, ranging from basic borescopes to advanced imaging systems inspired by medical endoscopy, are transforming how automotive professionals approach vehicle maintenance.

While these advanced tools require skilled operators and appropriate training, their benefits are undeniable. They enable:

- Non-invasive Inspection: Reducing unnecessary disassembly and labor time.

- Improved Diagnostic Accuracy: Visualizing internal components and defects with greater clarity and detail.

- Early Defect Detection: Identifying problems at an early stage, enabling preventative maintenance.

- Targeted Repairs: Pinpointing the exact location and nature of issues, minimizing unnecessary parts replacement.

- Enhanced Vehicle Reliability: Contributing to more effective repairs and preventative maintenance, improving overall vehicle lifespan and performance.

The future of automotive diagnostics will undoubtedly be shaped by continued advancements in endoscopic tools for cars and related imaging technologies. As these tools become more sophisticated and accessible, they will become even more integral to the automotive repair process, leading to more efficient, accurate, and cost-effective vehicle maintenance.

References

While direct references from the original medical article may not be perfectly applicable, here are some general categories of references relevant to “endoscopic tools for cars” that could be included in a real article:

- Automotive Diagnostic Equipment Manuals and Guides: Manuals from manufacturers of automotive endoscopes and related diagnostic tools.

- Technical Articles and Publications on Automotive Diagnostics: Articles from automotive repair magazines, journals, or online resources focusing on diagnostic techniques and tool reviews.

- SAE (Society of Automotive Engineers) Technical Papers: Relevant SAE papers on automotive inspection technologies and non-destructive testing methods.

- Websites of Automotive Endoscope Manufacturers: Links to product pages and technical specifications of various endoscopic tools for cars available on the market.

- Online Forums and Communities for Automotive Technicians: Links to relevant discussions and practical experiences shared by mechanics using endoscopic tools.

By focusing on these types of references, the article can maintain its credibility and provide valuable resources for readers interested in learning more about endoscopic tools for cars.